Special and Standard

Fasteners Distributor

Specialty Fastener Distributor

Searching for a reliable source of specialty fasteners? We are a full-service fastener distributor that offers top notch quality products. Everything from nuts and bolts, to screws, rivets and pins are covered here.

He have closely partnered with some of the best cold forming manufacturers in the world that produce high end, engineered to print fasteners of various kinds. We primarily stick to “engineered” fasteners and not standard fasteners (although we support those as well).

Specialty Fasteners

Many non-standard fasteners can be made by changing an existing fastener, which keeps costs and lead times down. If you need a standard product with, for example, a different head diameter, thread length, or pitch, we can get it for you.

Forging of coiled steel wire or rod into shape at room temperature using multiple dies and punches is the typical approach of our manufacturing partners. In some cases where machining is more advantageous, we can utilize that method as well.

Our diverse supply base is capable of high-speed forming, multiple dies for more complex shapes and requirements and customers enjoy parts with increased strength from cold working of material.

As a fastener supplier we have the the capability to perform line walks, evaluate efficiencies, design, consolidate multiple fasteners in to less fastener SKU’s required for production, etc.

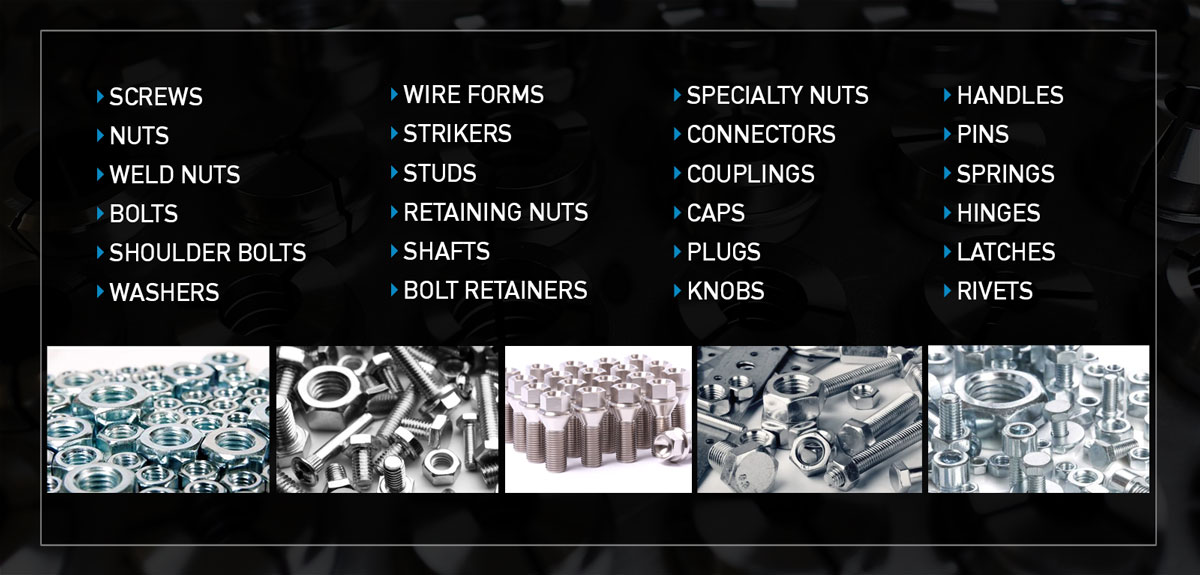

Our core fastener categories

- Screws

- Nuts

- Weld nuts

- Bolts

- Shoulder bolts

- Plastic injection moldings

- Washers

- Wire forms

- Strikers

- Studs

- Retaining Nuts

- Shafts

- Bolt Retainers

- Specialty Nuts

- Connectors

- Couplings

- Caps

- Plugs

- Knobs

- Handles

- Pins

- Cable ties

- Springs

- Hinges

- Latches

- Rivets

Fastener finishes we supply:

- Zinc

- Black Oxide

- Passivation

- Bolts

- Tin

- Phosphate & Oil

- Zinc nickel

- Aluminum Zinc

- Brite Dip

- Copper

- Nickel and Electroless Nickel Plating

- And many more

Specialty Fastener Sourcing

Our global fastener supply base has capability to produce automotive grade quality fasteners with Quality levels of less than 50PPM. While most of our key manufacturing partners are abroad (specifically Taiwan for fasteners), we have a variety of domestic manufacturers we often work with.

Our domestic fasteners manufacturers, have proven to be globally competitive in terms of cost and have automotive level manufacturing principles instilled throughout their operation.

Our sources are vetted, audited, qualified and have a strong and long track record of producing complex parts On-Quality, On-Cost and On-Time for Mechanical Power and its customer base. We also like taking advantage of the opportunity to add value for customers in the form of provided kits (kitting).

Multiple components are sourced, kitted in to a bag configuration of the customer’s choice and provided as a grouping of items that come in as one SKU.

Mechanical Power distribution facility and headquarters are ISO90001:2015 certified. Our manufacturing partners have at least ISO9001:2015 accreditations, however we put strong emphasis in our key manufacturing partners being TS/IATF certified.

FAQs

What is a fastener company?

A fastener company is an organization that makes or sells fasteners. Fasteners companies sell fasteners to consumers, contractors, and manufacturers. They also provide technical support and training to help customers use their products.

What is an OEM fastener?

Many sectors, particularly original equipment manufacturers, demand highly reliable and robust fasteners. Depending on project and application specifications, stainless steel fasteners may be required for the operation. OEM is an abbreviation for Original Equipment Manufacturer.

How are fasteners manufactured?

During cold forging, steel is shaped at room temperature into the desired form. Bolt heads are cold-headed to gradually shape the steel by forcing it through several dies under high pressure. It is possible to make threads by rolling or by cutting.

Industrial fasteners are typically manufactured using hot forging. In hot forging, the metal is heated to a high temperature before being formed. This method is frequently employed for mass production, and the resulting fastener is sturdy and long-lasting.

Screw machining is the technique of cutting threads into a workpiece using a machine tool. This is accomplished by inserting the workpiece into the machine and removing material from it using a cutting tool. Screw machining is one of the most precise machining techniques, and it may manufacture both internal and external threads.

Injection molding is an alternative method for producing industrial fasteners, and it offers several advantages over machining. Injection molding is quicker, more accurate, and generates less material waste. Additionally, injection-molded fasteners are frequently less expensive than machined ones.

Take the hassle out of global sourcing.

Contact us for your Industrial Fasteners needs.