Quality Assurance

Home /

Ensuring High Standards in Manufacturing and Production

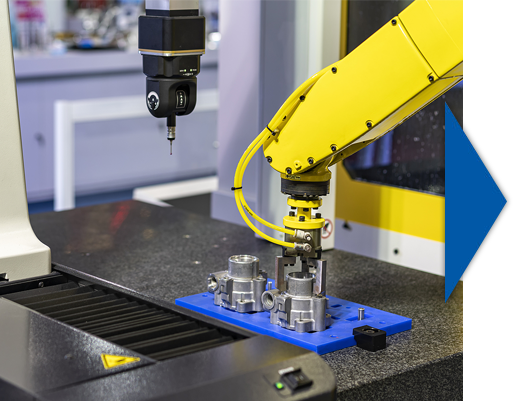

As an ISO certified hybrid manufacturer, our quality control throughout the supply chain has set it apart from the competition. We work primarily with TS & IATF certified manufacturers. This coupled with our in house quality assurance protocols and boots on the ground abroad results in world class incoming and outbound quality key performance metrics.

Quality Department – ISO Accredited Sourcing Company

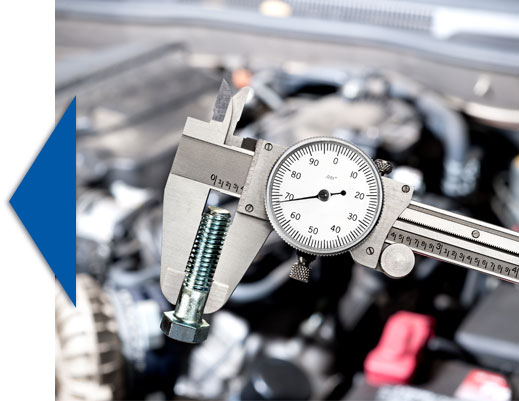

At Mechanical Power, our experienced team actively inspects incoming parts, ensuring the highest quality and adherence to your specifications.

Our rigorous in-house inspection process and supplier standards save you time and money. Partner with us for reliable, top-notch products and exceptional customer satisfaction.

Quality Assurance Summary

Capable with all PPAP levels

Facilitate PFMEA and DFMEA analysis

Physically audit and approve manufacturers before partnering

Audit key manufacturers annually

Executive leadership regularly visits key manufacturers

RoHS/REACH compliant

8D quality process – root cause ID & reoccurrence prevention

Committed to VA/VE initiatives on production parts

Reverse engineering – a core competency

In-House Inspection Process

All new suppliers parts are subject to an incoming inspection process at Mechanical Power.

The inspection size is randomly selected and a seasoned inspector verifies that the product conforms to the specification within the drawings and requirements you need.