Linear Roller Bearings

Home / Product Categories / Bearings /

Linear Roller Bearing Supplier

Linear bearings are a common type of bearing that are generally used in industrial machinery and equipment involving moving parts such as linear actuators, transport systems, machine tools, robots, and even sliding drawers.

These bearings are used in applications in which moving parts need to travel a certain distance with minimal resistance.

There are several types of linear bearings available and each application may require a different type of linear bearing to get the job done. When looking for linear bearing parts for your application, it is important to know the specifications of the machinery to find the right type of linear bearing.

Once you have determined this, you will then be faced with the daunting task of finding the exact parts for your linear bearings to suit your application.

At Mechanical Power, we can help businesses in multiple industries find the exact linear bearings they need with our global product sourcing services. We work with domestic and international manufacturers to quickly and efficiently find the exact parts you need and have them delivered in one package, saving your business time and money.

We provide our global product sourcing services for businesses in the Midwest and throughout the U.S.

What are linear bearings?

Linear bearings are bearings that guide moving parts in a linear motion. These bearings usually work by moving parts along a rail system that is usually a straight line, but it does not have to be. The length of the rail may vary depending on the application or type of machinery.

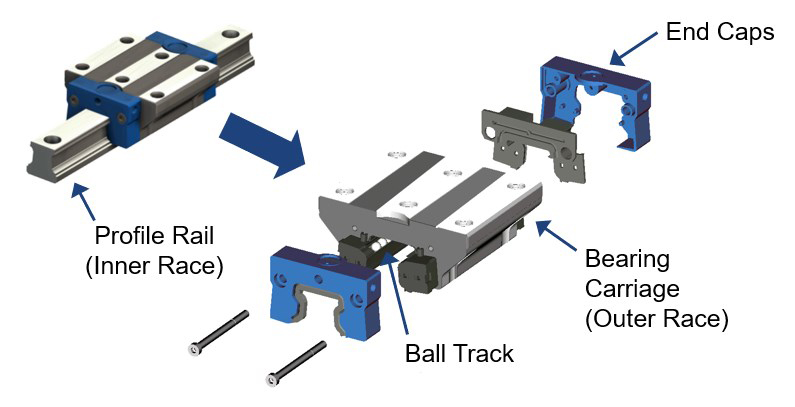

Linear bearings consist of roller bearings and a shaft or rail that the bearing rides. The roller bearings are typically cylindrical and ride along round shafts, but they can also be manufactured to ride irregularly shaped rails or tracks.

Roller bearings consist of an outer metal ring that may be open or closed and these rings contain rows of balls in the inner ring that move it along the shaft or track. The rails that the linear bearings ride may be flat, round, or complex in shape.

Types of Linear Bearings

Linear bearings are used in applications that require smooth movement with limited friction. These bearings are easy to maintain and replace, and they have high rigidity which makes them quite durable. The following are facts about linear bearings that are important to understand:

- Linear bearings can only move along shafts or rails made of hardened steel or stainless steel.

- These bearings have a higher rigidity than plain bearings.

- Linear bearings must be sealed to keep out debris and contaminants. Some applications may include wipers to sweep the rail or shaft before the slide passes.

- The roller bearings must be lubricated.

There are two main types of linear bearings that are manufactured; ball bearing slides and roller slides.

Ball Bearing Slides

The most commonly used linear bearings are ball bearing slides. These slides consist of ball bearings within the slide housing that move smoothly and precisely along a single-axis linear shaft or rail. The ball bearings within these slides are self-lubricating which makes them durable and reliable for lower load capacity applications.

Ball bearing slides are typically made from aluminum, hardened steel, or galvanized steel. The ball bearings within the slides are lined in rows on opposite sides of the slide for smooth, even movement. Depending on the application, the linear movement can be initiated by hand, inertia, or a drive mechanism.

Ball bearing slides are typically used in applications with low load capacities because the balls are vulnerable to abrasions and wear and tear. They are typically used for robotic assembly, high end appliances, various electronics, and furniture production. A common use for this type of linear bearing is for sliding drawers.

Roller Slides

Roller slides are linear slides that consist of a moving carriage with cylinder-shaped bearings that move over a stationary linear base. They are used to provide low friction movement and better control for heavy load capabilities, and they are typically powered by hand or inertia.

The rollers within these slides are crisscrossed at a 90-degree angle and housed within “V” shaped grooves on the top and base of the carriage. The carriages of roller slides are typically made from aluminum and the rollers and rods or rails that they ride on are typically made from steel.

Roller slides are stopped on either end of the rail by end caps that are usually made from stainless steel.

Roller slides are more suitable for heavier loads than ball bearing slides and they can handle low levels of dirt, dust, and other contaminants. However, they are not self-cleaning. They can also move along more than one axis with stacked slides or slides with double carriages. Roller slides also offer more consistency in movement and less erosion as they have line contact instead of point contact.

The line contact and ability to move along more than one axis make roller slides more capable of handling heavier loads than ball bearing slides. These slides can be used in numerous applications in manufacturing, linear stages, machine tools, conveyor units, photonics, medical equipment, and telecommunications equipment.

Linear Bearing Design

In most applications, linear bearings move in a straight line along the shafts or rails. However, it is possible for linear bearings to move along non-linear rails if necessary.

It is also important to consider wipers that ride in front of the bearings or seals to prevent contaminants from getting into the bearings. The seal also serves the purpose of keeping the lubricant within the bearing.

When it comes to linear bearing design, you must consider the load capability, rigidity, and accuracy needed for the specific application. The ease of maintenance should also be considered when designing systems requiring linear bearings.

The specific applications will also help determine which types of rollers you should use as well as the shape and material of the rail or shaft.

Linear Bearing Sourcing from Mechanical Power

With so many applications and options for linear bearing systems, finding the specific parts needed can be a hassle. You may have to go through different manufacturers to get the sliders, rails, and shafts that best suit your application.

At Mechanical Power, our staff will take the time to understand what you need for your specific application and source the parts you need from the top manufacturers around the globe. We will not only efficiently find the parts you need, but also make sure they are delivered to you in one package.

That is how Mechanical Power can make your global sourcing simplified and save your company time and money.