Introduction to Electropolishing Aluminum

Electropolishing aluminum is an electrochemical process that removes material from a metallic workpiece to improve surface finish, enhance corrosion resistance, and provide a high level of cleanliness and brightness. This process is essential in various industries, including aerospace, automotive, food processing, and medical equipment manufacturing.

The Electropolishing Process Explained

Preparing Aluminum for Electropolishing

Before electropolishing, aluminum parts undergo a thorough cleaning to remove any contaminants that could interfere with the process. The cleaning phase typically involves a series of chemical baths and ultrasonic cleaning procedures.

The Electropolishing Procedure

The actual electropolishing process involves submerging the aluminum part in a specialized electrolyte solution and applying an electrical current. This current causes the removal of material from the surface, smoothing out microscopic peaks and valleys and imparting a brilliant shine.

Optimizing Electropolishing Parameters for Aluminum

To achieve the desired surface quality, the voltage and temperature of the electrolyte solution must be meticulously controlled. The ideal parameters depend on the aluminum alloy and the required finish quality. The duration of the electropolishing process is crucial for achieving the correct surface finish. Too short, and the process may be ineffective; too long, and the part may become overpolished.

Once electropolished, aluminum parts require proper rinsing to remove any remaining electrolytic solution. Drying is then performed to prevent water spots and ensure the surface is entirely free of residues. Each part is carefully inspected to guarantee that the electropolishing process has been successful. Surface roughness measurements and visual inspections are standard practices to confirm the quality of the finish.

Benefits of Electropolishing Aluminum

Electropolishing aluminum significantly increases its corrosion resistance by creating a smoother surface, reducing sites where corrosive agents could initiate attacks. The process provides a mirror-like finish, substantially improving the visual appeal of aluminum parts. By eliminating surface imperfections, electropolishing extends the lifespan of aluminum components, which is crucial for high-performance applications.

Applications of Electropolished Aluminum

Automotive Industry

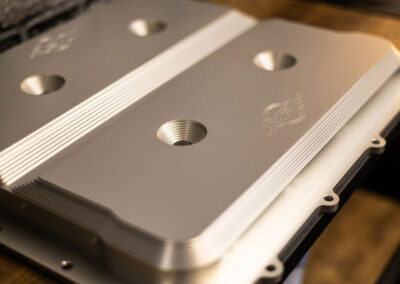

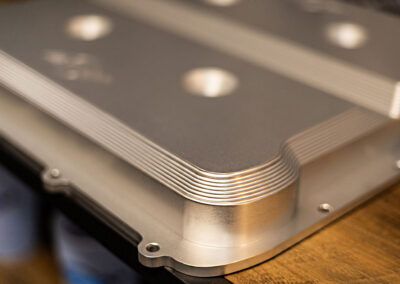

Supercharger Lid for LT4 Engines: A Case Study

The Supercharger Lid for LT4 Engines exemplifies the importance of surface finishing in automotive components. This critical piece is not only central to the engine’s performance but also to its reliability and efficiency.

Electropolishing the Supercharger Lid ensures that the surface is free from any micro-abrasions or irregularities, resulting in a smoother air passage that can significantly improve airflow efficiency. The polished surface aids in better heat dissipation, a critical factor in maintaining optimal performance of the supercharger and preventing overheating.

The visual aspect of automotive parts is increasingly important. A mirror-like finish on the Supercharger Lid accentuates the engine’s design, appealing to car enthusiasts who prize both performance and presentation. Road vehicles are exposed to a variety of contaminants. A smooth electropolished surface resists buildup of materials like oil and dirt, making it easier to clean and maintain.

Aerospace

Electropolished aluminum parts are used extensively in aerospace for their light weight and improved fatigue resistance.

Food Industry

The food industry favors electropolished aluminum for its easy cleaning and reduced bacterial adhesion.

Medical Devices

The biocompatibility and clean-ability of electropolished aluminum make it ideal for medical devices and implants.

Conclusion

Electropolishing aluminum is a superior finishing technique that not only enhances the visual aesthetics of aluminum parts but also contributes significantly to their performance and durability. Its application across various industries underscores its versatility and the value it brings to high-quality metal finishing.

By following this detailed approach to electropolishing aluminum, we offer a robust resource for professionals seeking to understand and implement this process in their operations. The comprehensive coverage provided here aims to deliver valuable insights for achieving top-tier results in aluminum finishing.

Resourceful and innovative Marketing Pro, with 20+ years of progressive experience in the marketing and creative technology industry. Responsible for digital and traditional marketing efforts that promotes brand awareness, increases engagement, and drives revenue.