Extrusion is a technique in which metal is fed into die holes of variable shapes to make products of various shapes. The Aluminum Association acknowledges extrusion as a popular process because aluminum extrusion products can be shaped creatively.

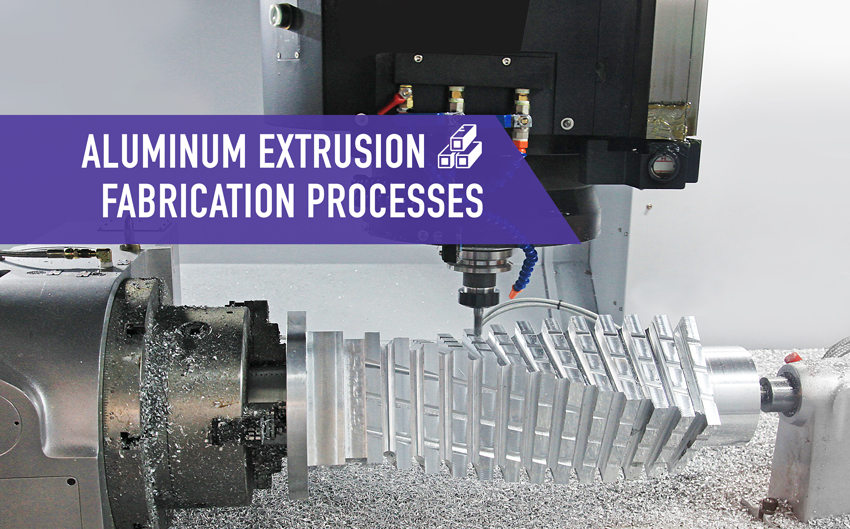

After aluminum has been extruded, fabrication commences. To create aluminum parts, aluminum extrusion fabrication includes precision cutting, computer numerically controlled (CNC) machining, mitering, punching, notching, drilling, and high-speed cutting.

Extruding the Aluminum Profile

Following the approval of the final profile design and the preparation of the die, the billet and extrusion tools are warmed in preparation for the aluminum extrusion process. The billet is moved to the cradle and crushed against the die until it comes into complete contact with the container walls.

Cooling the Profile

Depending on the alloy, the fully formed profile is cooled by high velocity, multi-sided air and water quench system that emits over 600 gallons per minute of water at over 130 pounds per square inch. Rapid cooling preserves extrusion profile traits, mechanical properties, and tolerances and ensures uniform and distortion-free cooling of any extrusion form.

Aluminum Extrusion Stretching, Cutting, and Aging

After the profile has been quenched (cooled), a “stretcher” is used to straighten the extrusion and repair any twisting that may have occurred. Additionally, the stretcher is utilized to apply cold work to the extrusion. The profile is then transported by conveyors to a saw where it is cut to predetermined lengths.

A secondary cutting process is utilized for the production of short lengths, miter cuts, and close tolerances. Depending on the aluminum alloy employed, aging or age-hardening may be necessary to achieve optimal strength, hardness, and flexibility.

Aluminum Surface Finishing

As soon as unprocessed aluminum is exposed to the atmosphere, it begins to create a protective oxide covering. For certain applications, aluminum profiles only require this thin, transparent oxide covering for protection. MPI has formed collaborations with many companies that specialize in a variety of extrusion finishes, such as Econ Welding or CMP anodizing if additional surface protection or an enhanced finish is sought.

Component Fabrication, CNC Machining, and Packaging

After adequate age, the aluminum profiles may be transferred to other parts of our facility for additional fabrication and machining, or they may be packed and prepared for export. The packaging of profiles protects them from surface damage, twisting, and other shipping, handling, and storage dangers.

Customers may define their own packaging specifications, or the type of extruded product may suggest a particular packing solution for storage or shipping convenience.

Working with Mechanical Power (MPI) requires cooperation. Following the examination of the initial aluminum profile design, we collaborate with your product development experts to create an aluminum profile that matches the specifications of the final product.

After the design of the aluminum profile has been approved, the aluminum extrusion die is created. Custom-designed aluminum extrusion dies can be manufactured in a fraction of the time required for other metal production processes, such as casting.

Resourceful and innovative Marketing Pro, with 20+ years of progressive experience in the marketing and creative technology industry. Responsible for digital and traditional marketing efforts that promotes brand awareness, increases engagement, and drives revenue.