In the complex world of modern business, effective supplier management is critical for success. Businesses rely on a network of suppliers to source goods and services, and the performance of these suppliers can significantly impact the quality, cost, and efficiency of their operations.

To manage and evaluate supplier performance, many organizations use a valuable tool called the “Supplier Scorecard.”

In this article, we will explore the fundamentals of Supplier Scorecards, their benefits, and how to create and utilize them for effective supplier management.

The Basics of Supplier Scorecards

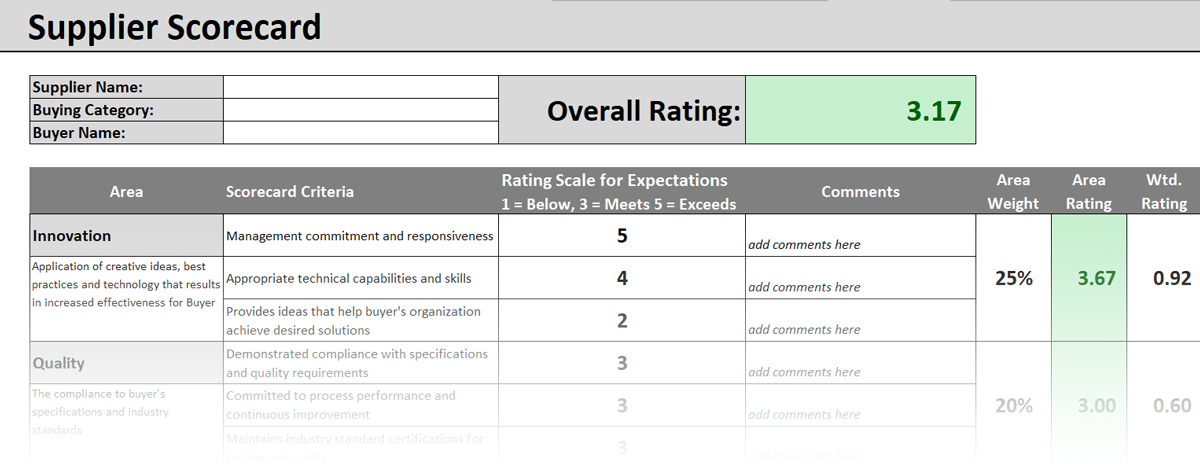

A Supplier Scorecard is a strategic tool that helps businesses assess and monitor the performance of their suppliers. It consists of several key components, including metrics and Key Performance Indicators (KPIs), performance criteria, and data collection methods. Here’s a closer look at these elements:

Metrics and KPIs

These are the measurable criteria used to evaluate a supplier’s performance. Metrics can include on-time delivery rates, product quality, cost-effectiveness, and more. KPIs are specific targets set for each metric, allowing businesses to track progress.

Performance Criteria

The performance criteria within a scorecard can be tailored to align with a company’s unique goals and objectives. For example, a manufacturing company may prioritize quality and on-time delivery, while a retailer may focus on inventory management and supplier responsiveness.

Data Collection Methods

To gather accurate data for supplier evaluation, businesses use a variety of methods, including surveys, on-site assessments, and data from Enterprise Resource Planning (ERP) systems. The data collected is then used to calculate performance scores.

Benefits of Supplier Scorecards

The adoption of Supplier Scorecards offers several key benefits to businesses:

Improved Supplier Performance

Regularly monitoring supplier performance encourages them to meet or exceed performance benchmarks. As a result, businesses can count on a more reliable and consistent supply of goods and services.

Enhanced Communication and Collaboration

Supplier Scorecards promote open communication between businesses and their suppliers. By sharing performance data and expectations, both parties can work together to identify areas for improvement and collaboratively drive better outcomes.

Risk Mitigation

By tracking supplier performance, businesses can identify potential issues early, allowing them to proactively address problems and reduce supply chain disruptions. This risk mitigation is crucial for maintaining business continuity.

Cost Savings

Improved supplier performance often leads to cost savings. Fewer defects, better delivery times, and optimized inventory levels can all contribute to reduced operational costs.

Creating an Effective Supplier Scorecard

To create an effective Supplier Scorecard, businesses should follow a structured approach:

Define Business Goals and Objectives

Start by identifying your organization’s overarching goals and objectives. What do you want to achieve through your supplier relationships? This could include reducing costs, enhancing product quality, or ensuring timely deliveries.

Select the Right Metrics and KPIs

Choose metrics and KPIs that align with your goals and objectives. Make sure they are quantifiable and relevant to supplier performance. Common metrics include quality, delivery, cost, and responsiveness.

Establish Performance Benchmarks

Set realistic performance benchmarks based on historical data, industry standards, and best practices. These benchmarks will serve as the basis for evaluating supplier performance.

Data Collection and Analysis

Implement robust data collection methods, ensuring the accuracy and reliability of the data collected. Leverage technology and data analytics to automate this process where possible.

Continuous Improvement and Feedback Mechanisms

A successful Supplier Scorecard is not a static tool. Regularly review and update your scorecard to reflect changing business objectives and market conditions. Provide feedback to suppliers and collaborate on action plans to address performance gaps.

Using Supplier Scorecards in Supplier Selection

Supplier Scorecards are not only valuable for managing existing supplier relationships but also for selecting new suppliers. During the supplier selection process, scorecards can help businesses:

Evaluate Potential Suppliers

Assess the performance of potential suppliers using the same metrics and KPIs as with existing suppliers. This data-driven approach can aid in making informed decisions about supplier selection.

Objective Decision-Making

Supplier Scorecards provide an objective basis for choosing suppliers. This reduces the risk of making decisions based solely on subjective factors and biases.

Identify High-Performing Suppliers

By analyzing the performance of existing suppliers, businesses can identify high-performing partners to consider for future collaboration.

Real-World Examples of Successful Supplier Scorecard Implementation

Let’s take a look at some real-world examples of businesses that have successfully implemented Supplier Scorecards:

Automotive Industry

Many leading automotive parts manufacturers use Supplier Scorecards to assess the performance of their supply chain partners. These scorecards focus on quality, delivery times, and cost efficiency to ensure that just-in-time manufacturing processes run smoothly.

Retail Giants

Large retail chains often use Supplier Scorecards to monitor supplier performance. For them, metrics related to inventory management, on-shelf availability, and lead times are crucial for maintaining optimal inventory levels and satisfying customer demands.

Global Sourcing Companies

At Mechanical Power, supplier scorecards are used to track and measure supplier performance. They can vary from simple to complex and can contain as much or as little criteria as deemed effective to accomplishing an organization’s goals. When used appropriately and consistently, supplier scorecards can strengthen relationships, improve costs and mitigate errors. Scorecards also provide an objective lens for measuring supplier performance.

At a base level, our scorecard includes the following criteria: Delivery, Compliance, Quality Service and Costs/Pricing

These examples highlight the versatility of Supplier Scorecards in various industries and their adaptability to specific performance criteria.

The Future of Supplier Scorecards

The future of Supplier Scorecards looks promising, with several trends and advancements on the horizon:

Technological Advancements and Automation

The adoption of advanced analytics, artificial intelligence, and automation will make it easier to collect, analyze, and report supplier performance data in real time.

Integration with Sustainability and CSR Metrics

As sustainability and Corporate Social Responsibility (CSR) gain prominence, Supplier Scorecards will likely include metrics related to environmental, social, and ethical aspects, allowing businesses to assess the sustainability of their supply chains.

Predictive Analytics in Supplier Management

Leveraging predictive analytics, businesses can anticipate potential supplier performance issues and take preventive measures before problems arise.

Data-Driven Success

Data-Driven Success

In an era where data is king, supplier scorecards empower companies to make data-driven decisions that lead to successful supplier selections and long-lasting partnerships.

Conclusion

In today’s highly competitive business environment, managing suppliers effectively is essential. Supplier Scorecards provide a data-driven approach to assess, monitor, and improve supplier performance. By creating and using Supplier Scorecards, businesses can realize significant benefits, from improved supplier performance to cost savings and risk mitigation.

As technology continues to advance, these scorecards will play an increasingly critical role in shaping the future of supplier management, driving collaboration, and promoting sustainability.

Incorporating Supplier Scorecards into your supplier management strategy is a proactive step that can help your business thrive in an ever-changing market. So, don’t hesitate to implement this invaluable tool to enhance your supplier relationships and secure your competitive edge.

Resourceful and innovative Marketing Pro, with 20+ years of progressive experience in the marketing and creative technology industry. Responsible for digital and traditional marketing efforts that promotes brand awareness, increases engagement, and drives revenue.

Data-Driven Success

Data-Driven Success