Reverse engineering is revolutionizing the innovation process of the world. The benefits of digitizing mechanical hardware into a digital interface allow engineers to manufacture, improve and reinvent it for the better.

Reverse Engineering

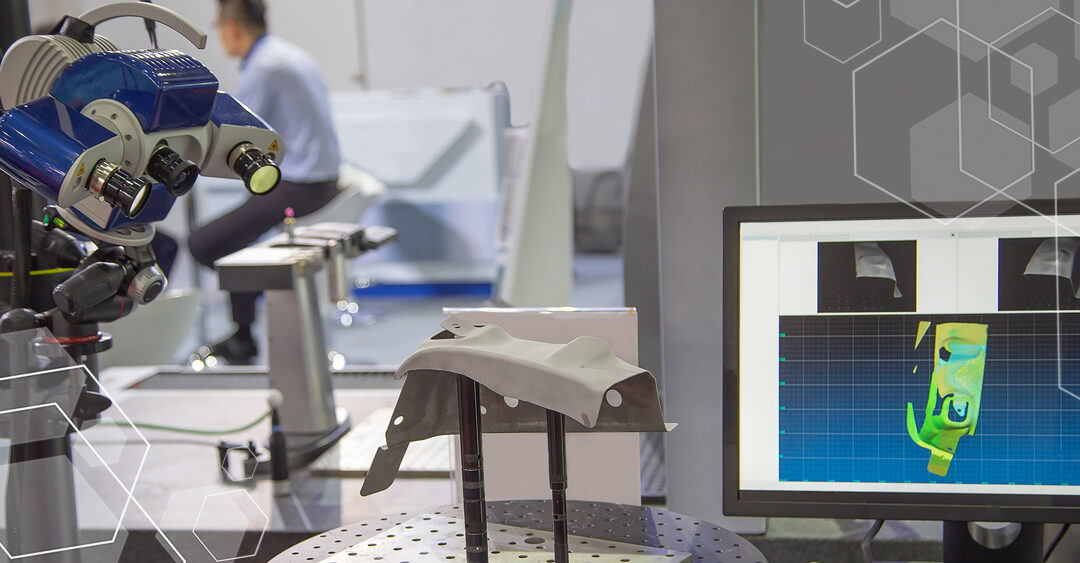

You can reverse engineer almost all hardware items, using a 3D scanner. Without 3D scanners, you have to do this by using manual measuring techniques and different. In a way, 3D scanning is the more advanced method of formulating the outline and layout of the hardware product.

For some, process of reverse engineering will involve taking a life object and measuring it with a tape measure or calipers. Then, they use those calculations and integrate them into the computing model. However, 3D scanners can now help with this process more easily. Mechanical Power utilizes cutting-edge scanning technologies to produce most accurate scan data.

Ultimately, the reverse engineering process with the help of 3D scanners helps derive an original blueprint from a product. Our engineers primarily use this technology in two areas, one includes software, and the other is mechanical engineering and tool making.

For the software use case, reverse engineering helps recover the source code. Whereas, tool making involves making a high precision 3D model of an existing model.

Break Down of the Process

To begin the process of reverse engineering, you have to simply take a mechanical object with complicated geometry, and laser scan that particular part, and convert that data into different codes, such as point cloud, NURBS, and then finally into a CAD model.

CAD stands for computer-aided design. You can find many interfaces that allow you to create designs with precise dimensions and measurements. Many designers use this digital platform to create engineering designs because it is more efficient and accurate.

Once the 3D scanner helps recreate the item in the computer in the form of a CAD, then you can reproduce it with the help of multiple manufacturing processes. Some of those processes of reverse engineering can include:

- Obsolete Part Replacement

- High-Value Part Replacement

- Rapid Prototyping

Ultimately, reverse engineering can be an excellent solution to your needs in many instances. Some of those criteria include:

- When certain parts are difficult to manufacture and have freeform surfaces

- If the value of a certain part is too expensive

- When the value of the part becomes obsolete and discontinued

- The part is Low cost but the volume is too high

- Long lead time

- Parts that are difficult to obtain from OEM

Some examples of reverse engineering items that can be useful for engineers and industries include hydraulic cylinders, bearings, impellers, valves, gas kits, gearboxes, and bushings. Parts such as these have a tricky geometry and thus, the reverse engineering process using 3D scanners allows you to make to recreate curvy and awkward structures with innovative precision.

Scan data is incredibly useful for speeding up the process and making the final model more accurate. Even if a particular object is not organic in shape, having to draw multiple features that easily correspond to each other accurately can be entirely difficult. Thus, for any shape or design, 3D scanning will save you from the time-consuming measuring process.

Methods of Reverse Engineering

The workflow of reverse engineering differs according to certain tasks. To start, there is the design intent workflow, and the auto surface workflow. A typical design intent method involves replicating a real-life object on the CAD software.

For this method, you need to have control of the dimensions of the hardware, along with an overall insight into the specific model. Hence, to get this model to come together, you have to build it up to feature by feature. The scan data in this workflow is more or less a reference that you use to ensure that the object is dimensionally accurate.

Moreover, you can also compare the actual hardware model, to the scan data you have collected, for deviation analysis. The auto surface workflow, as the name suggests, allows you to 3D scan something without having to use any integrated features. In this method, you can build the virtual geometry of the hardware by using the scan directly. In other words, the computer does most of the hard work.

For example, if you want to create a component for your cars, such as a bumper or any part that is custom fit into your car to precise dimensions, then you can take a model that you already have and 3D scan it to the same proportions.

The difference between this process and the design intent model is that manufacturers are devoid of the dimensional control that allows them to make relative changes. Nevertheless, the auto surface workflow is easier and less time-consuming.

To Conclude

Reverse engineering is an incredible industry with huge potential. It is an example of what computing is truly capable of and learning the modeling techniques and the functionality of different software will surely put you ahead of the curve.

Resourceful and innovative Marketing Pro, with 20+ years of progressive experience in the marketing and creative technology industry. Responsible for digital and traditional marketing efforts that promotes brand awareness, increases engagement, and drives revenue.