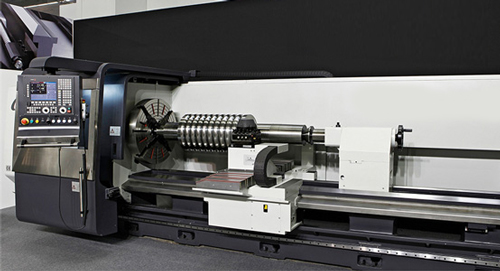

A CNC milling machine parts

Bed

The hardened part of the machine that carries all the load. All the other components are mounted over the bed. It is made of hard metal, and as the tool turret travels over this part.

- Headstock: It is the main part of the CNC machine. The workpiece is fixed on the headstock to carry out the desired operation. Also, this part has the main motor that works the main spindle.

- Tailstock: This part is to give extra grip to your workpiece during tough operations such as threading and knurling.

- Tailstock Quill: Tailstock quill helps unify the workpiece among tailstock and headstock.

- Pedal Or Foot Switch: The pedal is used to close and open the chuck while gripping the component.

- Chuck: It is present on the main spindle where you fix the workpiece for further process.

- Control Panel: This part is used to feed or set the program for working. Due to its main function in the machine, it is also called the brain of the custom CNC machining.

Elements Of CNC Machine

A CNC machining system usually consists of if the following elements.

Program

A program is the computer input that is typically performed by a keyboard. It tells the machine to perform a function or the given functional control code. These control codes are available in two sets, i.e., M-codes and G-codes.

G-codes are used to command the machine regarding the machine’s particular movements, including the drilling function o machine movements. M-codes stands for miscellaneous machine commands that do not apprehend axis movement.

Tape Reader

In injection molding and CNC machining, the tape reader is used as a storage device where you can store the program for a specific machining working. The programs are easy to modify, where you can edit the current program according to the requirement.

Mini-Computer

The mini-computer is the main control of a CNC machine. It is used to interpret the input to the language understandable to the computer to manage these functions:

- To initiate or stop the machine’s spindle.

- To fluctuate the spindle speed consequently

- To regulate the direction of rotation of the spindle

- To begin or stop the supply of coolant

- To control the feed rate or change the workpiece

- To vary the required tools as per requirement

Another benefit of a mini-computer is that it comes with diagnostic software that detects issues or problems with the computer and then restores it.

Servo System

The servo system’s main function is to get the control signal from feedback tools and then fix the output in response to the machine parts.

A servo system consists of:

- Feedback devices

- Servo motors

- Balls screws

Receive a Free Quote on CNC Machining Components!

Resourceful and innovative Marketing Pro, with 20+ years of progressive experience in the marketing and creative technology industry. Responsible for digital and traditional marketing efforts that promotes brand awareness, increases engagement, and drives revenue.