Background

Our customer is the leading global manufacturer of the widest range of hose, cord and cable reels for industrial, commercial and professional applications. Their key focus is to produce durable, quality products that make hoses, cords, and cables more productive, keep them easily accessible and make them last longer.

Customer manufactures the widest range of hose, cord, and cable reels as diverse as heavy-duty hose reels used in the light, medium, and heavy industry, automotive service, and a wide variety of OEM applications. These models include spring retractable, motor driven, and hand crank reels, handling hose lengths up to six hundred feet and ranging from ¼ inch to 4 inches in diameter and beyond.

Reels are used to transfer anything from air, water, transmission fluid, grease, oils, antifreeze, diesel fuels, welding gases, liquid pesticides, fertilizers, detergents, solvents, chemicals.

Challenge/Opportunity

Customer was experiencing poor operating results when disassembling or breaking fifty feet roller chain into three-foot sections.

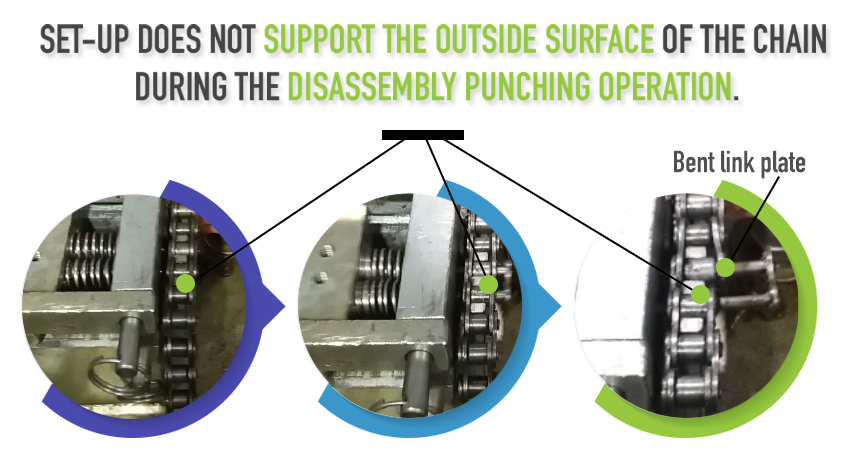

Operator was bending the chain link plates, it was not breaking properly, and as a result their assembly line when down.

Customer was certain the chain was the issue, because as per customer “We have been using the same process and machine/fixture for years with no issues, now we have them, therefore the chain is the issue”. The customer did not focus on anything than the chain because they have done the same process with the same machine/fixture for years

Root Cause Investigation

MPI’s Quality team placed all inventory in a hold location so the engineering team could initiate their root cause investigation.

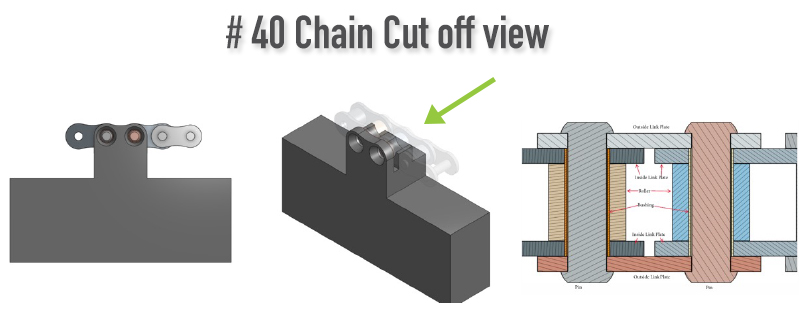

MPI’s engineering team went to work immediately and reviewed the chain specification, did a complete dimensional lay out on all inventory, and disassembled a few links with a Chain Pin Extractor Tool.

Engineering team did not see the same issue as customer was experiencing. After requesting more information, MPI noticed that the customer current set-up did not support the outside surface of the chain during the disassembly punching operation.

As a result, the force applied to the riveted pins by the two punches is transferred locally throughout the chain assembly. This causes the press-fit bushings (inside link plates) to push out of the link plates resulting in a failure of one or both adjoining pitch assemblies.

Solution

Engineering began to work on an alternative machine/fixture that would eliminate the link plate bending issues. MPI’s proposal would fully support the pitch assembly being disassembled (punched) and isolate the punching force to only the two pins being pressed out.

This would result in a clean disassembly of the pitch being punched out and avoid disassembly / deformation of the adjoining pitch assemblies.

Resourceful and innovative Marketing Pro, with 20+ years of progressive experience in the marketing and creative technology industry. Responsible for digital and traditional marketing efforts that promotes brand awareness, increases engagement, and drives revenue.