Introduction

In the competitive landscape of modern industries, the concepts of Value Analysis (VA) and Value Engineering (VE) have emerged as crucial methodologies for enhancing product value and operational efficiency. These twin strategies, collectively known as VAVE, are instrumental in reducing costs while improving product functionality and product quality.

Table of Contents

Historical Background of VAVE

VAVE’s roots trace back to the mid-20th century, initially developed to tackle resource shortages during wartime. Over the years, it evolved into a systematic approach adopted by various industries to optimize product development and manufacturing processes.

Understanding Value Analysis (VA)

Value Analysis focuses on existing product lines, scrutinizing each component to ensure it contributes effectively to the product’s overall functionality. The primary goal of VA is to identify and eliminate unnecessary costs without sacrificing quality. This process involves a series of steps, including gathering information, generating ideas, and implementing solutions.

Exploring Value Engineering (VE)

While Value Analysis is retrospective, Value Engineering is applied during the product development stage. VE aims to achieve optimum value by balancing functionality and costs. Unlike VA, VE is more proactive and creative, often leading to innovative solutions that redefine product design and performance.

Did You Know?

For more than forty years Mechanical Power has been supplying high-quality bearing at competitive prices from around the world. We are best known for sourcing the highest-quality industrial parts at competitive prices from around the world.

Maximize efficiency of your equipment.

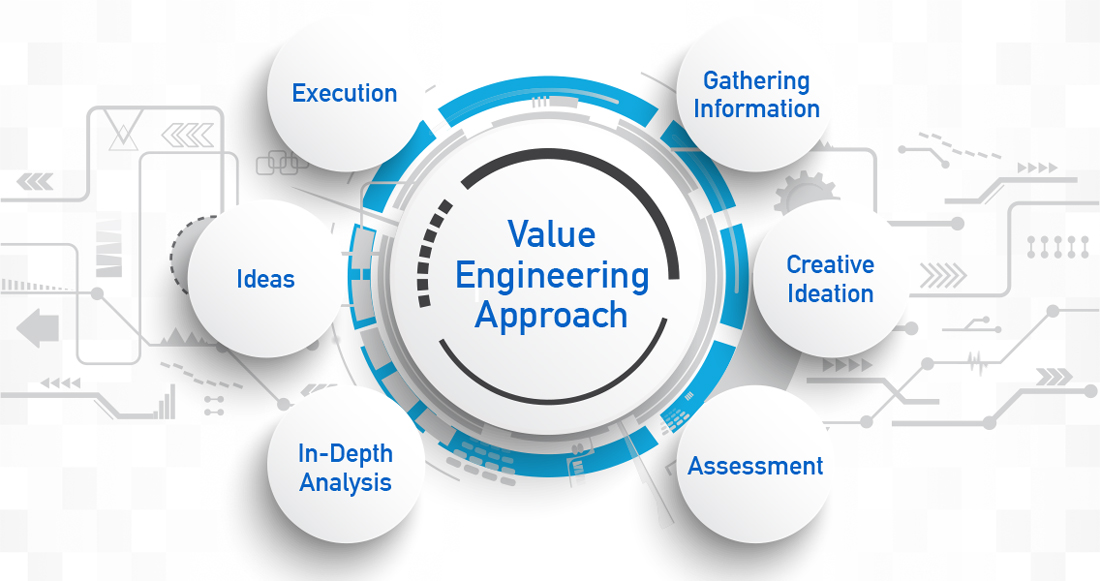

Value Engineering Approach:

For sustained success in Value Engineering, a structured approach is essential. What are the key components of an effective VA/VE strategy, and which steps are involved?

- Gathering Information: Study the costs and functional needs.

- Creative Ideation: Pinpoint potential solutions and new ideas.

- Assessment: Review the ideas for further advancement.

- In-Depth Analysis: Thoroughly explore the selected concepts.

- Communication: Discuss the ideas with key stakeholders.

- Execution: Implement the selected plan.

VAVE in Product Development

Integrating VAVE in product development ensures that every design element is cost-effective and adds value to the end product. This integration results in products that not only meet but exceed customer expectations in terms of quality and functionality.

VAVE Tools and Techniques

Several tools, such as Functional Analysis, FAST (Function Analysis System Technique), and Cost-Worth Analysis, are employed in VAVE to identify areas for improvement. These tools help in systematically breaking down products or processes and evaluating their components for cost-effectiveness and utility.

Challenges and Solutions in Implementing VAVE

Implementing VAVE is not without challenges. Resistance to change and a lack of understanding of VAVE principles are common hurdles. To overcome these, organizations need to invest in training and foster a culture of continuous improvement and innovation.

Future Trends in VAVE

The future of VAVE is promising, with advancements in technology like AI and machine learning offering new avenues for analysis and innovation. These technologies can provide deeper insights and more efficient ways to apply VAVE principles.

Conclusion

VAVE remains a vital tool for various industries aiming to enhance value and efficiency. Its principles are timeless, and its adaptability to evolving market and technological trends makes it an enduring methodology for success.

Resourceful and innovative Marketing Pro, with 20+ years of progressive experience in the marketing and creative technology industry. Responsible for digital and traditional marketing efforts that promotes brand awareness, increases engagement, and drives revenue.