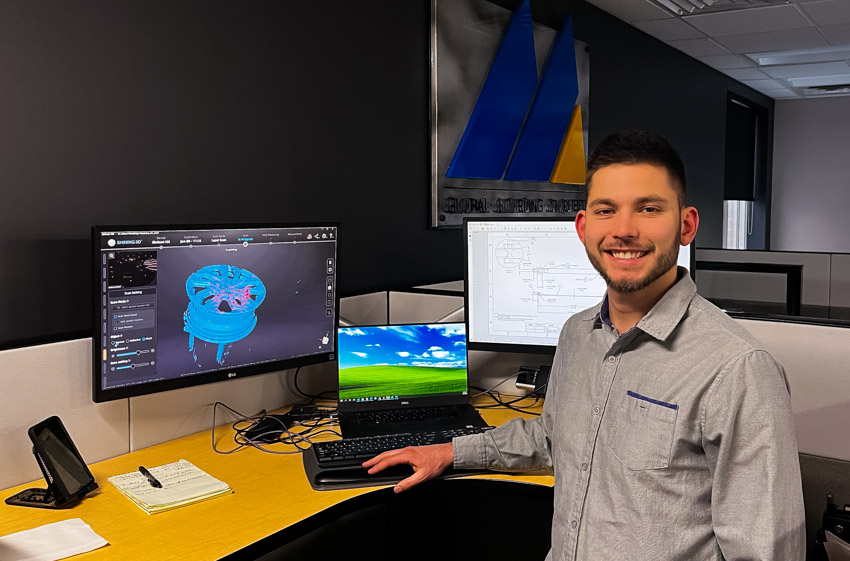

The process of 3D scanning an object is simple, however, taking the actual process of taking that 3D scan data and creating an actual CAD model is somewhat different. At Mechanical Power we use cutting-edge hardware and software to create the CAD models to eliminated errors and improve product development timeline.

Process of scanning an object using a scanner, and exporting it to an SDL file, does not take much time, however, processes that follow require much more time and effort.

Much of this process is repetitive and monotonous. Sometimes it also requires us to do a bit of guesswork, and all of this is achievable after constant practice and learning.

What is Scan Data, and why is it gaining popularity

Scan Data’s popularity is due to the advancements of reverse engineering popularity. The hardware and software involved are getting more powerful, and at the same time economical for the public. You can also find multiple different solutions that incorporate this technology at different budgets.

Scanners themselves range from inexpensive desktop systems to accurate arm-based solutions that combine CMM and scanning techniques. Some manufacturers even tend to combine high precision with the flexibility of handheld solutions. One example of this includes the Creaform handyscan scanners.

Even if you do not personally possess a scanner, or cannot afford one, you can now hire a 3d scanning service such us Mechanical Power, that will scan a particular part for you.

What Makes Up Scan Data?

You can find two main types of scan files, point cloud, and mesh. Point clouds consist of million points in cyberspace. These points represent the surfaces of a part. Since there are so many points aligned accurately across the structure of the object, they form dimensions that are consistently accurate to the 3D image.

With a mesh file, triangle-forming lines represent the points in the point cloud. What this means, is that the 3D file will consist of millions of tiny triangles. The most common file type in mesh formation is an SDL. People that already use 3D printers will recognize this file format easily since it is most common for 3D printers.

Is It Easy to Work with Scan Data?

Due to optimizing and automation of reverse engineering technology, using scan data technology is now simple. 3D scanners are much easier to operate, and you always have the option of hiring a service provider. Either way, once you are in possession of your scan file, you will find multiple options for working with scan data.

The complexity is very much dependent on the size of the data, along with the functions you are particularly looking for. If you have a very small SDL file, one option would be to use an interface and integrate that file as either a solid surface or graphic body.

Furthermore, you can find many online platforms that have new tools, which involve the mesh modeling toolbar that increases the usability of the scan data. You can also use an array of different AD-ins that aim to make simpler parts. Alternatively, this Ad-in feature also helps you work with larger and more complex parts.

Mechanical Power’s modern reverse engineering capabilities will improve your entire manufacturing process. Once you understand this cause-and-effect process, the high demand for globally outsourced manufacturing parts makes more sense.

We closely monitoring advances, in the tech world that further enhance our capabilities to help OEM customers with reverse engineering initiatives and serving as an extension of their quality, engineering, and supply chain departments.

Resourceful and innovative Marketing Pro, with 20+ years of progressive experience in the marketing and creative technology industry. Responsible for digital and traditional marketing efforts that promotes brand awareness, increases engagement, and drives revenue.