A combine harvester, also known as a combine, is a large agricultural machine that is used to harvest crops such as wheat, corn, soybeans, and other grains. It combines several different functions into one machine, including cutting, threshing, and cleaning the grain.

The combine harvester is typically pulled by a tractor and has a cutting platform at the front that cuts the stalks of the crops and feeds them into the machine. Inside the combine, a threshing drum separates the grain from the straw and chaff, while a cleaning system removes any remaining debris. The grain is then stored in a hopper or transferred to a trailer for transport.

Modern combines are often equipped with advanced technologies such as GPS, yield mapping, and automated controls, which help to optimize the harvesting process and improve efficiency. They are widely used in large-scale agriculture and have revolutionized the way that crops are harvested, making the process faster, more efficient, and more reliable.

There are several companies that provide OEM (original equipment manufacturer) parts for agriculture equipment. Some of the major manufacturers of combine harvesters and their associated OEM parts suppliers include:

Mechanical parts commonly used in a combine harvester

Reel

The reel of a combine harvester is a rotating component that helps to lift the crop from the ground and move it towards the cutter bar. The reel is made up of several parts, including:

Reel bats

These are the metal arms that extend from the reel shaft and rotate to lift the crop.

Fingers

These are smaller metal tines that are attached to the reel bats and help to lift the crop.

Bearings

These are the bearings that support the reel shaft and allow it to rotate smoothly.

Drive

This is the mechanism that drives the reel shaft and makes it rotate.

Speed control

This is the mechanism that allows the operator to control the speed of the reel rotation.

Height adjustment

This is the mechanism that allows the operator to adjust the height of the reel to suit the crop height.

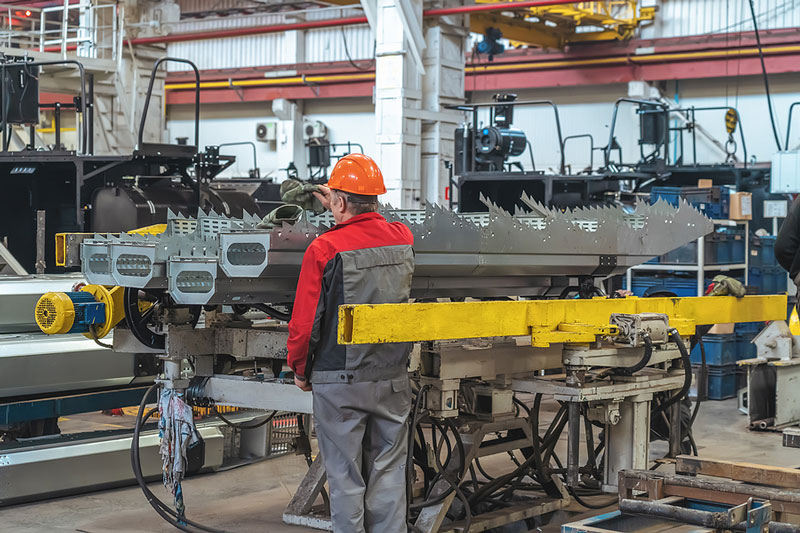

Cutter bar

The cutter bar is a critical component of a combine harvester that cuts the crop as it moves through the field. The cutter bar is typically made up of several parts, including:

Knife sections

These are the blades that are mounted on the cutter bar and do the actual cutting of the crop.

Guards

These are metal plates that are mounted over the knife sections to protect them from damage.

Hold-downs

These are metal fingers that help to hold the crop in place as it is being cut.

Reel fingers

These are the same metal tines that are attached to the reel and help to lift the crop towards the cutter bar.

Knife drive

This is the mechanism that drives the knife sections and makes them cut the crop.

Knife speed control

This is the mechanism that allows the operator to control the speed of the knife sections.

Threshing drum

The threshing drum is a component of a combine harvester that separates the grain from the straw and chaff. It is a cylindrical drum that rotates and contains a series of bars, teeth or rasp bars that rub against the crop as it passes through.

The threshing drum is made up of several parts, including:

Drum bars

These are the bars that are mounted around the circumference of the drum and do the threshing.

Concaves

These are curved plates that are mounted inside the threshing drum and help to separate the grain from the straw and chaff.

Rasp bars

These are metal bars with teeth or projections that rub against the crop as it passes through the drum, helping to separate the grain from the straw and chaff.

Drum bearings

These are the bearings that support the threshing drum and allow it to rotate smoothly.

Unloading auger parts

The unloading auger is a mechanical arm that extends from the grain tank of a combine harvester and unloads the harvested grain into a trailer or storage bin. It is made up of several parts, including:

Auger tube

This is a long metal tube that extends from the grain tank to the unloading point.

Auger flighting

This is a spiral-shaped metal blade that runs the length of the auger tube and moves the grain towards the unloading point.

Flighting bearings

These are the bearings that support the auger flighting and allow it to rotate smoothly.

Unloading spout

This is the component of the unloading auger that directs the grain into the trailer or storage bin.

Unloading spout extension

This is an optional component that can be attached to the unloading spout to increase the reach of the unloading auger.

Unloading spout positioner

This is the mechanism that allows the operator to adjust the position of the unloading spout to direct the grain into the desired location.

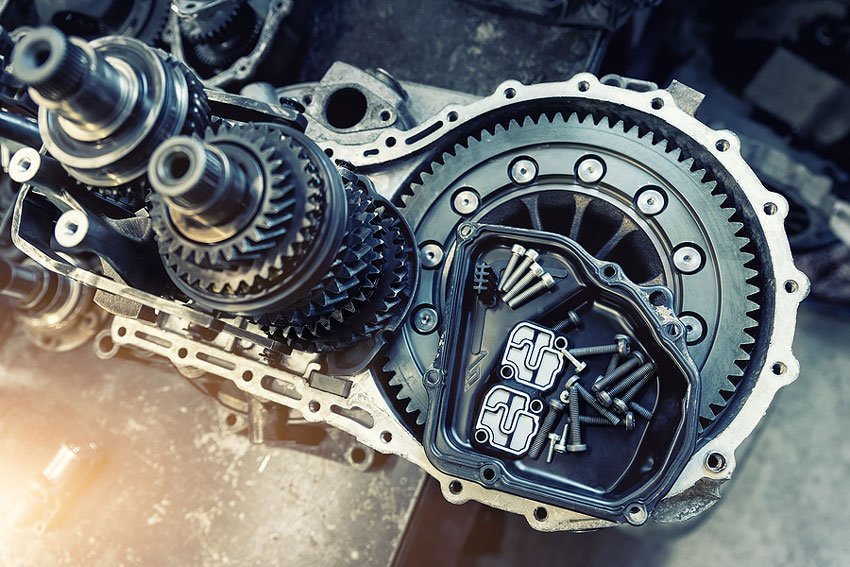

The transmission and engine of a combine harvester are two of its most important components.

Here are some of the parts that can be found in each transmission:

Transmission housing

This is the casing that encloses the gears and other components of the transmission.

Gears

These are the toothed wheels that transmit power from the engine to the wheels and other moving parts of the combine harvester.

Shafts

These are the metal rods that connect the gears and other components of the transmission.

Clutch

This is the mechanism that engages and disengages the transmission from the engine, allowing the operator to control the speed and direction of the combine harvester.

Hydraulic system

This is the system that provides pressure and fluid to control the clutch and other components of the transmission.

All of these parts work together to power and control the combine harvester, allowing it to efficiently harvest and process crops. Proper maintenance and adjustment of the transmission and engine is crucial for the smooth and reliable operation of the combine harvester.

Replacing parts in a combine harvester

Replacing parts in a combine harvester is crucial to maintaining optimal performance and preventing breakdowns. Worn-out parts can lead to decreased efficiency, increased fuel consumption, and even complete machine failure.

Regular maintenance and timely replacement of parts can help ensure a longer lifespan for the machine and ultimately save farmers time and money in the long run.

Suppliers to OEMs (original equipment manufacturers) are companies that provide components or subsystems to be used in the manufacture of a finished product by the OEM. In the case of combine harvesters, suppliers to OEMs provide various components and subsystems that are used in the assembly of the combine harvester.

Suppliers and parts distributors for combine harvester parts can provide high-quality parts that are specifically designed for the make and model of the machine.

They often have a wide range of parts in stock and can quickly source and deliver parts that may be more difficult to find. Additionally, many suppliers and distributors offer warranties or guarantees on their products, providing farmers with added peace of mind.

Overall, working with reputable suppliers and parts distributors can help ensure that your combine harvester is equipped with the right parts to perform at its best.

Some of the common suppliers to OEMs for combine harvesters include:

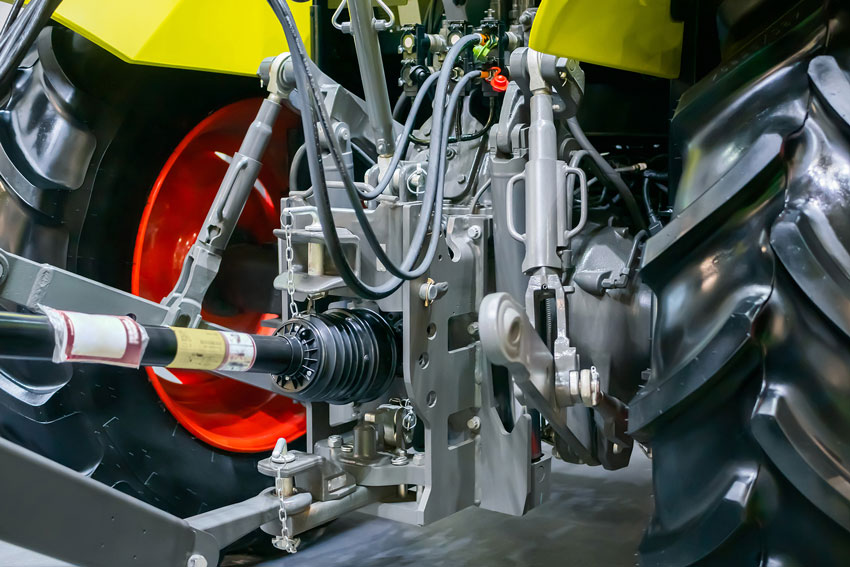

Engines and drivetrains

Suppliers of engines, transmissions, and other drivetrain components to OEMs include companies such as Cummins, AGCO Power, Deutz, Mechanical Power and Caterpillar.

Cutting and threshing components

Suppliers of cutting and threshing components to OEMs include companies such as Schumacher, Claas, Honeybee, and MacDon.

Electrical and hydraulic systems

Suppliers of electrical and hydraulic systems to OEMs include companies such as Eaton, Parker Hannifin, Mechanical Power, Danfoss, and Bosch Rexroth.

These suppliers work closely with the OEMs to develop and manufacture high-quality components that meet the specific needs of combine harvester manufacturers.

They often provide technical support, design expertise, and quality control to ensure that their components meet the rigorous standards of the combine harvester industry.

Looking for high-quality, OEM parts for your combine harvester? We offer a wide range of reliable and durable parts to keep your agriculture equipment running smoothly and efficiently.

Resourceful and innovative Marketing Pro, with 20+ years of progressive experience in the marketing and creative technology industry. Responsible for digital and traditional marketing efforts that promotes brand awareness, increases engagement, and drives revenue.