Reverse Engineering for Industrial Parts

Industrial Reverse Engineering: Replicate. Improve. Future-Proof Your Components.

At Mechanical Power, reverse engineering isn’t a secondary service—it’s a cornerstone of what we do. When critical components become obsolete, when drawings are lost, or when quality and cost need to be reevaluated, companies turn to us. We take your physical part—no matter how complex—and recreate it with unmatched accuracy and efficiency.

Our team of experienced engineers combines technical expertise with cutting-edge tools to reconstruct components down to the finest detail. From dimensional scanning to metallurgical analysis, we uncover what makes a part work—and how to make it better.

Engineering Precision Starts with Understanding

The key to successful reverse engineering lies in asking the right questions—and having the right tools to find the answers. At the start of every project, our engineers take the time to understand not just the physical part, but its purpose, the environment it operates in, and the role it plays in your overall system.

That insight allows us to go far beyond measurements. We evaluate the form, fit, and function of every component, ensuring the final design isn’t just a replica—but a fully functional, optimized solution. Whether your goal is replication, improvement, or innovation, we make it happen.

Tools That Drive Results

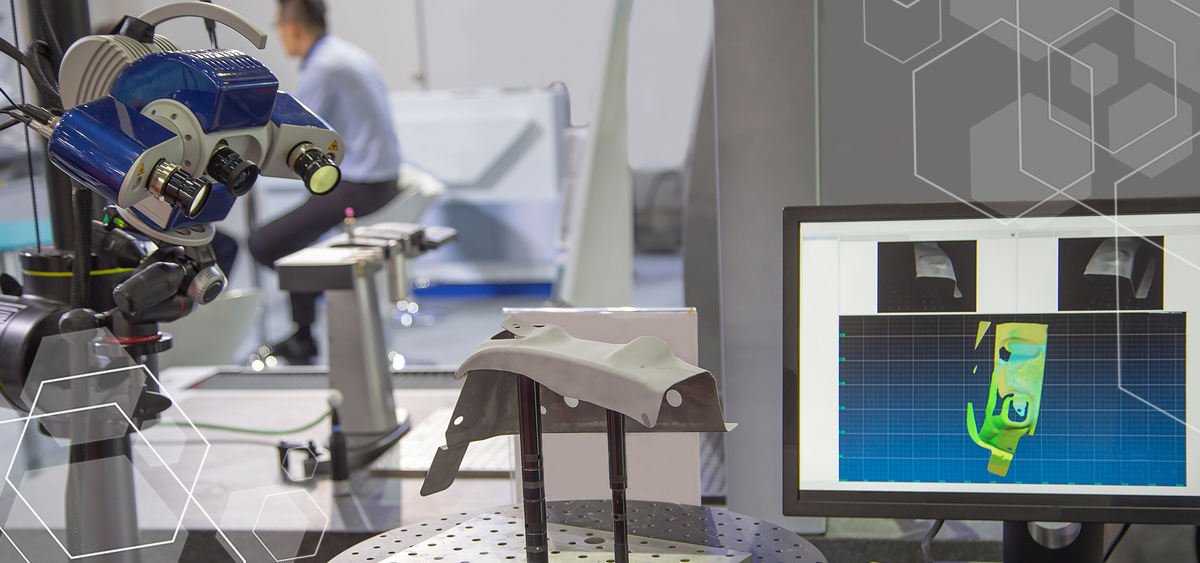

Inside our in-house lab, precision is our default. Our process often begins with a CMM (Coordinate Measuring Machine) or robotic arm scanner that captures detailed geometries of even the most complex parts. These digital scans are transformed into CAD models by our team, who use them to create accurate engineering drawings and 3D renderings.

When necessary, we partner with trusted third-party labs to analyze material composition—especially for legacy components with unknown properties. The result is a complete, production-ready blueprint ready to enter your supply chain.

Real Results: Lawn Care Industry Case Study

One of our most impactful reverse engineering projects came from a major player in the lawn care industry. Their goal was to reduce supply chain costs and gain control over critical aftermarket components. With no existing prints and a costly supplier base, they needed a partner who could help them rebuild from the ground up.

Mechanical Power reverse engineered the necessary parts, created precise documentation, and sourced superior alternatives—cutting their annual costs by nearly 30%. We didn’t just replicate components; we reshaped their sourcing strategy and elevated their operational efficiency.

Industries We Support

Reverse engineering plays a pivotal role across the industries we serve. From lawn and garden equipment to industrial manufacturing and heavy machinery, the need for accurate, reliable component replication is constant. In many cases, reverse engineering is the only viable solution when original manufacturers go out of business or documentation becomes unavailable.

Whether you’re maintaining aging equipment, prototyping a new design, or replacing failed components, Mechanical Power ensures you’re not left without a solution.

A Strategic Partner in Engineering

Reverse engineering is more than problem-solving—it’s risk prevention, cost savings, and competitive advantage. At Mechanical Power, we don’t just deliver parts. We deliver peace of mind, backed by decades of experience and a network of global manufacturing partners ready to produce the components we recreate.

Let us help you take control of your component designs and future-proof your operations with expert reverse engineering solutions.

Reverse Engineering Services and Best-in-class CMM Equipment

Maximize the efficiency of your business. You can reach out to Mechanical Power and get to know more information about our reverse engineering services.

Frequently Asked Questions

What types of parts can be reverse engineered?

Mechanical Power can reverse engineer most mechanical components, including cast, machined, and molded parts—regardless of complexity.

Can you reverse engineer a part if I don’t have the original drawing?

Absolutely. Our team uses 3D scanning and measurement tools to digitally reconstruct parts from physical samples.

How do you verify material properties?

We use in-house testing methods and partner with third-party metallurgical labs for detailed material analysis when needed.

How long does the process typically take?

Turnaround times vary by project, but most reverse engineering jobs are completed within 2 to 6 weeks.

Do you help with production after reverse engineering is complete?

Yes, we offer complete sourcing solutions to take your engineered components into full production through our global supplier network.

Got Questions? We will put you on the right path.

Ask about our reverse engineering services – our highly trained experts are standing by.