Are you looking for a new conveyor system? Conveyors and conveyor systems are used to move products and materials along the supply chain from one location to another.

When it comes to selecting a conveyor system, things can get tricky. Ensuring your production line moves material at the right rate, while keeping the environment free of dust and maintenance issues, can be quite a challenge.

As an integral part of modern material handling, industrial conveyor systems add both efficiency and safety. Where manual product transportation was time-consuming and hazardous to employees in the past, using today’s conveyor systems allows for fast and safe material flow, saving time, money and keeping employees safer.

Heavy duty industrial conveyors used in conveyor automation include live rollers, belt driven live roller and zero pressure and offer flexible solutions for warehouse environments.

Conveyor Types

Many types of conveyor are available in new or used condition and can be customized to the specific needs of each individual company.

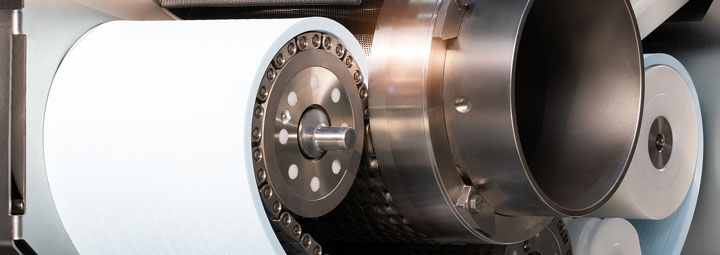

Belt Drive Conveyors

Belt drive units are one of the most frequently used forms of conveyors, with a straightforward – and low-cost – means of conveying things from point A to point B. Belt conveyors are built in a multiple ways, but they are all made up of modular plastic or continuous flexible belts that are controlled by pulleys or sprockets. They can move a wide range of product shapes, sizes, and weights while keeping complete control.

Belt conveyors are utilized in innumerable production lines, warehouses, fulfillment centers, various sortation systems, and even applications that need transporting bulk goods, and can be configured into various layouts including inclines/declines and curves.

Roller Conveyors

Roller conveyors transport items and materials by using parallel-mounted rollers that allow for smooth movement. They can be designed in a variety of different ways. The most basic format is gravity roller, in which the rollers are unpowered and the products freely move along them. When mounted on a slight incline, gravity will provide the motive force in that direction.

Furthermore, skatewheel gravity conveyors work in the same way as roller gravity conveyors, but instead of rollers, a series of narrow skatewheels are mounted and “roll” more easily, allowing for use with lighter packages.

Chain driven live roller (CDLR)

Another design is the chain driven live roller (CDLR), which employs a combination of rollers and sprockets connected by a chain. This type is commonly used for moving heavy items with flat bottoms, such as pallets. Because of their powered control and ability to withstand harsh operating conditions, CDLR conveyors are advantageous.

Options include product accumulation, in which the line continues to run but the products line up in a queue on the conveyor. As an industry workhorse, this type of conveyor is frequently used for delivery systems in assembly lines, packaging facilities, food processing applications, and a variety of other applications.

Motorized Roller Conveyors

One of the most recent roller conveyor system designs addresses the question: instead of a single motor driving all rollers simultaneously, what if a small motor is placed inside the roller? Each of these motorized rollers would use drive bands to power its own section of rollers – or even a short belt – thereby creating individual “zones.” To meet the needs, various levels of control are available. When the space is clear, photo-eye sensors activate the motorized roller, causing products to move from zone to zone for zero-pressure accumulation.

This advanced type of conveyor operates on low voltage power, allowing for simple plug-and-play installation. This design is especially useful in warehousing, distribution, and various assembly/manufacturing applications, allowing for smoother, more precise product movement along the line without contact.

Chain Conveyors

Chain conveyor systems are built tough by combining chains and sprockets with appropriate frames and drives. They are available in a variety of designs, including floor mounted and overhead models, to meet the needs of a wide range of applications. Floor-mounted conveyors are commonly used in applications requiring the movement of heavy objects such as pallets, gaylords, and drums.

This design is also used in many styles of right-angle transfers. They can be found in assembly and packaging lines, as well as in a variety of industries including pharmaceutical, cosmetics, and consumer goods. When floor space is limited in warehousing, distribution, and manufacturing projects, an overhead continuous chain conveyor can be used to transport or return products, parts, packaging materials, and containers.

Vertical Conveyors

Vertical conveyors are a catch-all term for systems that raise or lower products from one area to another at a different elevation or on a different floor, combining several types of conveyors into a single category. Spiral conveyors, which use a special belt or chain in a rotary vertical motion to change elevation for products while taking up less floor space than an incline, are a common type.

Vertical lift conveyors are another type and are classified as either reciprocating or continuous, both of which are extremely versatile. Conveyors of this type are used in a variety of applications, including warehouse/distribution centers, pharmaceutical plants, food and beverage processing, general manufacturing, and consumer goods production.

Conveyor Systems Parts Sourcing

Whether you are in the market for new, used or refurbished conveyor, MPI can help with sourcing replacement components. Our team of professional conveyor parts experts will assist you with finding the items you need at a price you can afford.

Our goal is to make your conveyor parts purchasing experience a good one. From explaining the different automated material handling systems available to providing engineering and control systems support.

We offer simplified global sourcing services which will ensure that you get the right parts for your conveyor system so you can devote your company’s resources to moving product. Mechanical Power can source the following parts to keep your conveyor belt systems running: Belt Conveyor Parts, Shaft Collar, Conveyor Roller parts, Linear Bearings or Roller Chains.

Mechanical Power (MPI) is the industry leader in conveyor systems components. We have more than 45 years of experience helping customers like you select and implement the right conveyor system for their needs.

Our parts are designed to help your system move material consistently and efficiently, while minimizing dusting and maintenance requirements. When the time comes to make a component sourcing decision, let MPI show you why we’re the industry leader in conveyor systems.

Our highly experienced team is dedicated to providing cost-efficient solutions tailored to meet the requirements of particular applications. Contact us to today and improve your bottom line.

Resourceful and innovative Marketing Pro, with 20+ years of progressive experience in the marketing and creative technology industry. Responsible for digital and traditional marketing efforts that promotes brand awareness, increases engagement, and drives revenue.