Introduction

In the automotive industry, buyers and procurement professionals face a constant balancing act between cost, quality, and uptime. The distinction between OEM (Original Equipment Manufacturer) and MRO (Maintenance, Repair, and Operations) sourcing plays a critical role in how efficiently operations run—and how competitive manufacturers remain.

While OEM sourcing focuses on components that go directly into vehicle production, MRO sourcing ensures that manufacturing equipment, conveyors, and assembly lines stay operational. Understanding the difference can help procurement teams refine strategies, reduce downtime, and build more resilient supply chains.

At Mechanical Power, we support both OEM and MRO buyers with high-quality industrial components, global sourcing solutions, and inventory management programs that keep production moving without compromise.

What Are OEM Parts?

OEM parts are precision-engineered components manufactured to exact design specifications. They are typically used by automotive manufacturers or Tier 1 suppliers assembling vehicles or key subassemblies.

OEM sourcing focuses on consistency, certification, and reliability. Each part must meet rigorous performance standards and maintain traceability throughout production.

Examples of OEM components include:

Bearings, bushings, and fasteners used in drivetrains

Engine and suspension components

Hydraulic fittings and nozzles

Chains, sprockets, and pulleys in power transmission systems

For many buyers, partnering with a company experienced in domestic or global sourcing allows them to maintain OEM quality while improving cost structure and delivery flexibility.

What Are MRO Parts?

MRO (Maintenance, Repair, and Operations) covers everything needed to keep automotive facilities running efficiently—from bearings in conveyor systems to seals, fasteners, and replacement chains.

Unlike OEM parts, which are tied to specific vehicle builds, MRO items are used to support production infrastructure. These are the parts that prevent costly downtime and maintain output consistency across shifts.

MRO buyers face different challenges than OEM teams. They must manage unpredictable demand, short lead times, and inventory complexity. In this space, availability and responsiveness matter as much as cost.

Mechanical Power’s inventory management and supply chain management programs help buyers maintain reliable access to essential parts—without tying up working capital.

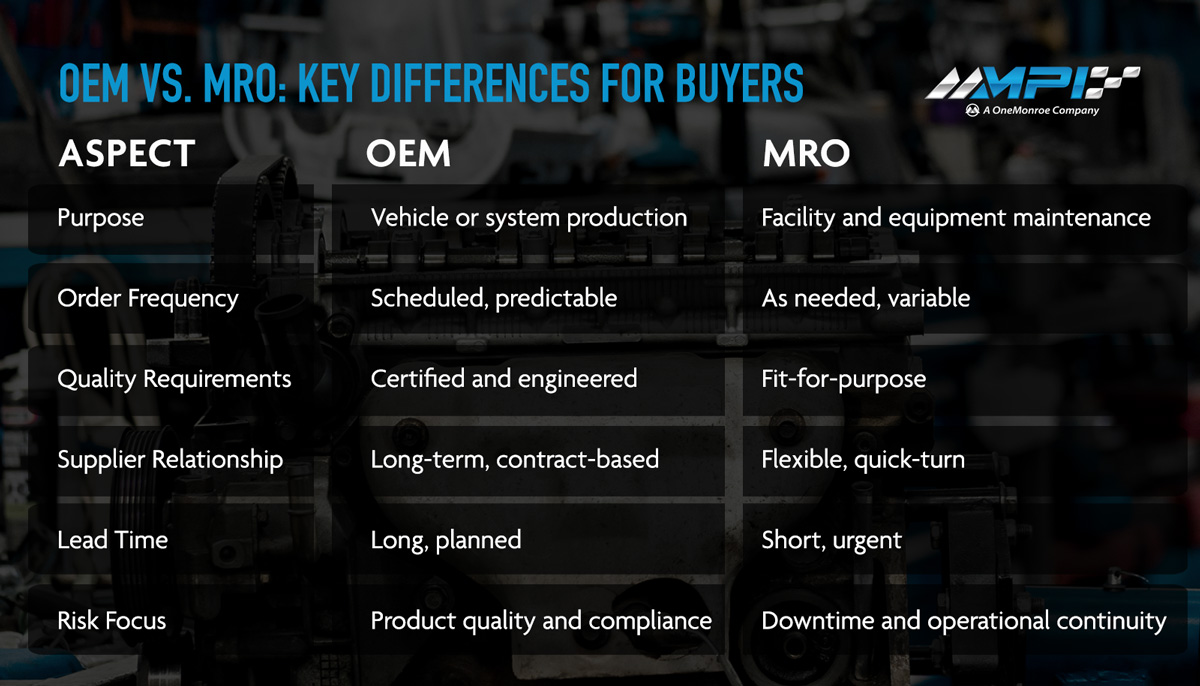

OEM vs. MRO: Key Differences for Buyers

OEM focuses on long-term production precision, while MRO centers on operational uptime and flexibility.

Challenges Facing Automotive Procurement Teams

Procurement leaders across the automotive sector face evolving challenges:

Supply chain disruptions and global material shortages

Rising logistics costs and limited supplier diversity

Pressure to localize production while maintaining global competitiveness

Obsolete or hard-to-source components that require reverse engineering

Through reverse engineering, MPI helps automotive buyers replace obsolete OEM parts with precision alternatives that meet or exceed original performance standards—helping reduce downtime and extend asset life.

How OEM and MRO Strategies Work Together

The most successful procurement organizations align their OEM and MRO strategies into one cohesive supply chain approach.

OEM relationships ensure design integrity and production consistency.

MRO programs safeguard uptime and throughput.

Strategic sourcing partners like MPI connect both sides through data-driven planning, inventory management, and flexible supplier networks.

By integrating OEM and MRO sourcing strategies, buyers can:

Reduce supplier fragmentation

Standardize quality across part types

Leverage volume for better pricing

Predict and prevent downtime through proactive stocking

How Can MPI Help You?

We can supply all of your Automotive Parts needs.

Click the RFQ button, email us at [email protected]

or call us at 847.487.0070 for more information.

Tell us what you need and we will save you time and money.

Conclusion

In today’s automotive landscape, the line between OEM and MRO sourcing is increasingly interconnected. Each plays a vital role in maintaining performance, quality, and profitability.

For purchasing and procurement professionals, understanding this balance—and partnering with a sourcing specialist who can manage both—means fewer disruptions, more predictable costs, and greater long-term success.

Mechanical Power bridges the gap between OEM precision and MRO agility. Through global sourcing, inventory management, and domestic manufacturing, we help automotive companies secure the components they need—when they need them.