In today’s fast-paced business environment, efficient inventory management is crucial for maintaining a competitive edge. Many organizations are turning to Warehouse Barcode Inventory Management solutions to enhance accuracy, streamline operations, and gain real-time visibility into their inventory. In this blog post, we’ll explore the ins and outs of Warehouse Barcode Inventory Management and discuss its importance in optimizing warehouse processes.

Understanding Warehouse Barcode Inventory Management

Warehouse Barcode Inventory Management is a system that utilizes barcode technology to track and manage inventory items throughout a warehouse or distribution center. Barcodes are unique identifiers represented by a series of parallel lines, and they can be found on products, shelves, and bins. When scanned, these barcodes provide information about the item, allowing for precise tracking and management.

The Basics of Barcode Technology

Before delving into the benefits of Warehouse Barcode Inventory Management, it’s important to understand the basics of barcode technology. Barcodes come in two main types: 1D (one-dimensional) and 2D (two-dimensional). 1D barcodes are the traditional lines and spaces you see on most products, while 2D barcodes are more complex and can store more information. Barcodes are generated using barcode software and can be scanned with barcode scanners, which are essential tools for inventory management.

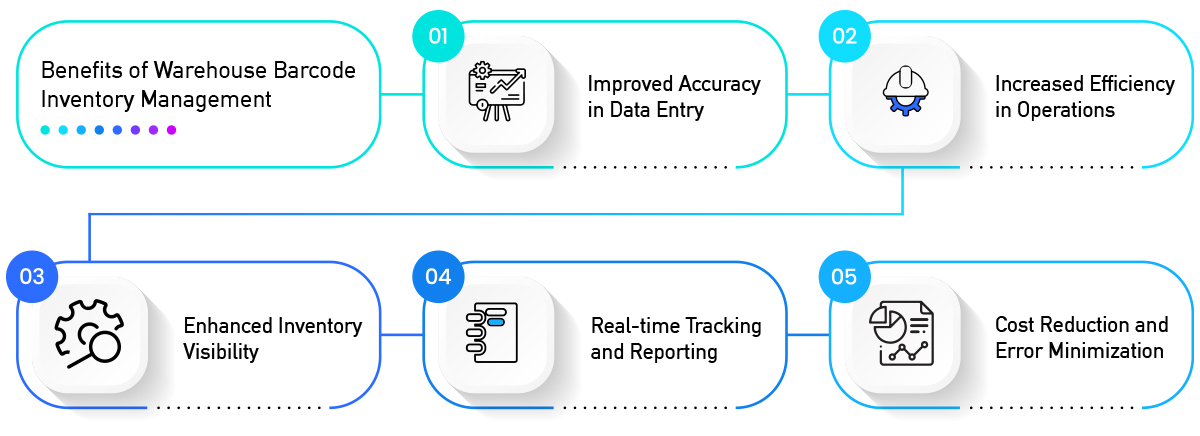

Benefits of Warehouse Barcode Inventory Management

Implementing Warehouse Barcode Inventory Management offers a wide range of benefits, including:

Improved Accuracy in Data Entry

Barcodes significantly reduce the risk of manual data entry errors, which can lead to costly mistakes in inventory management.

Increased Efficiency in Operations

Scanning barcodes is faster and more accurate than manual data entry, leading to quicker and more efficient processes.

Enhanced Inventory Visibility

Barcodes provide real-time visibility into the status and location of inventory items, enabling better decision-making.

Real-time Tracking and Reporting

Barcode systems offer real-time tracking capabilities, allowing organizations to monitor inventory movement instantly.

Cost Reduction and Error Minimization

By minimizing errors and improving efficiency, barcode systems help reduce operational costs.

Implementing Barcode Inventory Management Solutions

To implement Warehouse Barcode Inventory Management successfully, consider the following steps:

Selecting the Right Barcode Scanners and Printers

Choose equipment that suits your specific warehouse needs, considering factors like volume, environment, and connectivity.

Barcode Label Design and Printing

Create clear and consistent barcode labels that are easy to scan and contain essential information.

Integration with Warehouse Management Systems (WMS)

Integrate your barcode system with your WMS for a seamless flow of data and inventory control.

Employee Training and Change Management

Ensure that your team is properly trained in barcode system usage and create a transition plan for a smooth adoption process.

Case Studies

Real-world case studies demonstrate the tangible benefits of Warehouse Barcode Inventory Management. Companies that have successfully implemented barcode systems have reported improved accuracy, faster order fulfillment, and significant cost savings. Some popular providers of barcode systems in the United States include:

Zebra Technologies

Zebra offers a wide range of barcode scanners and printers designed for various industries, including warehousing.

Honeywell (formerly Intermec)

Honeywell provides advanced data capture solutions, including mobile computers and barcode scanners.

Datalogic

Datalogic’s barcode scanners and mobile computers are known for their performance and durability.

SATO America

SATO offers label printing solutions, including industrial printers and thermal transfer labels.

Trends and Innovations

The world of Warehouse Barcode Inventory Management is constantly evolving. Some emerging trends and innovations include:

Mobile Barcode Scanning Apps

Mobile apps are becoming more popular for barcode scanning, allowing for greater flexibility and mobility.

IoT and RFID Integration

The integration of Internet of Things (IoT) devices and RFID technology can provide even more granular tracking and data collection.

Machine Learning and AI in Inventory Forecasting

Advanced technologies like machine learning and artificial intelligence are being used for predictive inventory management and demand forecasting.

Sustainability and Eco-friendly Barcode Solutions

More companies are considering the environmental impact of their barcode systems, leading to the development of eco-friendly options.

Conclusion

Warehouse Barcode Inventory Management is a powerful tool for organizations looking to optimize their warehouse operations. With the right barcode system in place, companies can enjoy increased accuracy, enhanced efficiency, and better inventory visibility. As technology continues to advance, the future of warehouse inventory management with barcodes looks promising.

In the United States, popular barcode system providers include Zebra Technologies, Honeywell, Datalogic, and SATO America. When considering a barcode system for your warehouse, research these providers to find the solution that best fits your needs and budget.

By embracing Warehouse Barcode Inventory Management and staying informed about industry trends, your business can stay ahead of the competition and achieve a more efficient and cost-effective warehouse operation.

Resourceful and innovative Marketing Pro, with 20+ years of progressive experience in the marketing and creative technology industry. Responsible for digital and traditional marketing efforts that promotes brand awareness, increases engagement, and drives revenue.