Powder coating is an advanced method of applying paint to metal components, providing a durable layer of protection and superior resistance to corrosion. The powder is applied electrostatically and is then cured with heat in order to create a high-quality finish that adheres well to the substrate. Powder coating is typically used in the automotive, aerospace, lawn & garden, and industrial industries.

This type of coating system feeds chips or powder particles electrostatically to a spray gun, which heats and sprays the powder onto the substrate. This process ensures an even coating of the components and creates a finish that is resistant to scratches, abrasion, and corrosion.

Powder coating also offers an array of color choices, with custom tint options available as well. The finished product is easy to clean and maintain due to its smooth surface and long-term pressure resistance.

The durability and strength of the coating are superior to older painting techniques, such as liquid painting. The powder is sprayed onto the substrate and then accelerated in an oven to fuse into an anti-corrosive layer, preventing harsh weather conditions from deteriorating it.

This process also creates a seductive finish on items, enhancing their aesthetics as well as their useful life. It can be applied to many metals like iron, aluminum, galvanized steel, stainless steel, brass and copper for stronger results than other conventional coatings.

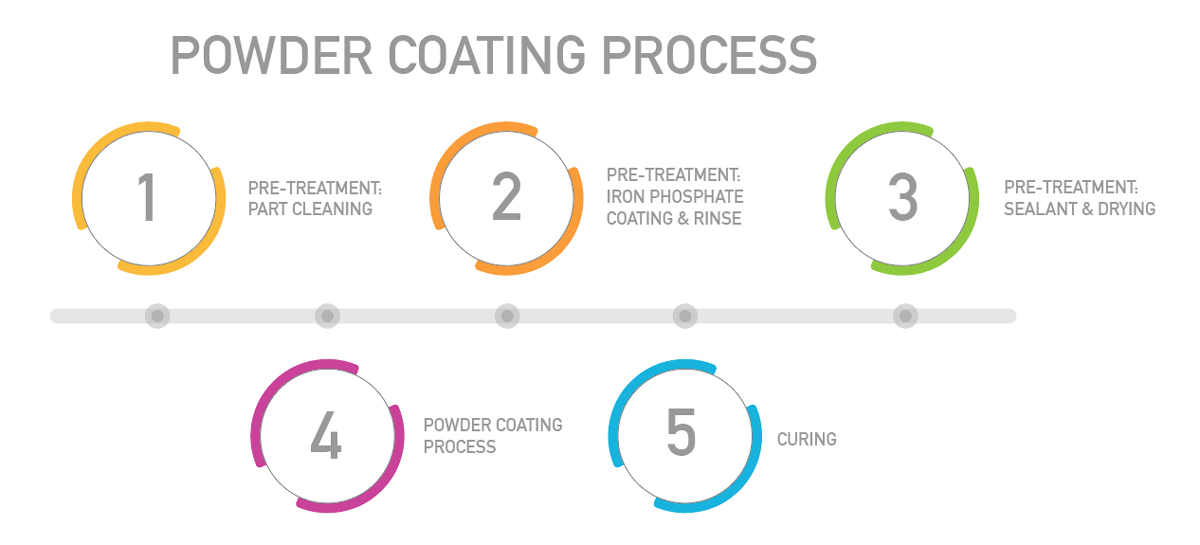

Process of Powder Coating

The actual process of powder coating is quite simple. The item to be coated is cleaned and pre-treated with chemicals to prepare it for the finishing step. Then, a powdered coating material is electrostatically applied with special equipment. The coated parts are then baked in an oven in order to fully cure and harden the finish, creating a strong bond between the part and the product.

The end result is a durable, attractive finish that can last a long time if properly cared for. Additionally, powder coating comes in numerous colors and textures so you can always find something that’s aesthetically pleasing.

This process adds a layer of protection from wear, tear, rusting, corrosion, abrasion, and fading. It also helps seal out moisture and chemicals that can otherwise cause damage.

Powder coating is also an eco-friendly finishing method as it doesn’t produce any VOCs (Volatile Organic Compounds) in the air or ground. In today’s world where environmental awareness is increasing rapidly, this makes powder coating an attractive option for industrial applications.

Powder Coating Advantage

Powder coating offers the advantage of being a more ecological choice compared to paint or other finishes. Unlike traditional wet painting, powder coating does not require an external solvents and emits few VOCs.

This means it is safer for both the environment and workers alike as it produces less hazardous waste and has fewer emissions than other typical finishes. Additionally, powder coatings are also resistant to corrosion and resistant to most chemicals and abrasive materials, making them perfect for items that need constant exposure outdoors.

Key Markets & Applications

Powder coatings are frequently used in outdoor equipment and parts that need outstanding durability, vibrant colors, and fading resistance. Powder coatings are often used on metal gutters, facades, bathroom fittings, and aluminum doors and windows in architecture.

Powder coatings are also often used on playground equipment, fire hydrants, lawn equipment, vehicle parts, and home appliances.

AGRICULTURAL & CONSTRUCTION

Storage systems

Tractors

Trailers

Cranes

Ploughs

Earth moving equipment

Fork lift trucks

APPLIANCE

Gas and electric ranges

Refrigerator doors and shelves

Washing machines and dryers

Freezers

Water heaters

Vacuum cleaners

Kitchen appliances

Microwave ovens

Garbage disposals

Dishwashers

AUTOMOTIVE & TRANSPORTATION

Primers

Wheels

Bumpers

Window trims

Door handles

Windshield wipers

Steering wheels

Radiators

Suspension systems

Oil/air filters

Shock absorbers

Valve covers

Brake assemblies

Mirror brackets

Truck seat frames

Chassis

ELECTRICAL

Motor windings and housings

Transformers

Switch gears

Electric junction boxes

Electric connectors

Electrical cabinets

Lighting fixtures

Telecommunications

GENERAL METAL

Playground equipment

Bicycle frames/wheels

Golf carts & clubs

Ski poles

Exercise equipment

Metal toys & wagons

Fans

Wheelchairs

Gasoline pumps

Toolboxes

Motorcycles

Mopeds

Fire extinguishers

LAWN & GARDEN

Lawn mowers

Fertilizer spreaders

Snow blowers

Barbecue grills

Chainsaws

Garden tools

Wheelbarrows

Edgers

Garden tillers

Snow Shovels

Patio furniture

Pros and Cons of Powder Coating

Powder Coating Pros

Classic look

Matte finish with a little sheen (satin)

More color options

Will hold up no problem over time

More cost effective

Powder Coating Cons

Can be boring depending on color

Bottom side not done (doesn’t really matter)

Not as unique as the anodized finish

Sensitive to nicks – be careful in storing and installation

Are you cosidering powder coating for your next project?

We hope this article will help you decide if powder coating is the best option for you next application.

Resourceful and innovative Marketing Pro, with 20+ years of progressive experience in the marketing and creative technology industry. Responsible for digital and traditional marketing efforts that promotes brand awareness, increases engagement, and drives revenue.