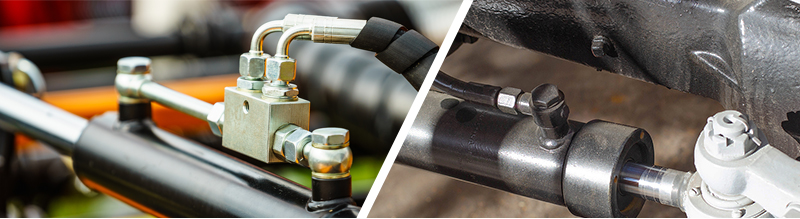

Piston seals are dynamic seals which can either be single acting or double acting. Generally, Elastomer seals made from nitrile rubber, Polyurethane or other materials are best in lower temperature environments, while seals made of Fluorocarbon Viton are better for higher temperatures.

There are also Metallic seals which commonly use cast iron for their seal material. Rod seals are dynamic seals and are generally single acting. The compounds of rod seals are nitrile rubber, Polyurethane, or Fluorocarbon Viton.

Wipers / scrapers, which are parts of the seal gland are used to eliminate contaminants such as moisture, dirt, and dust, which can cause extensive damage to cylinder walls, rods, seals and other components. The common compound for wipers is polyurethane.

Metallic scrapers are used for subzero temperature applications, and applications where foreign materials can deposit on the rod. The bearing elements / wear bands are used to eliminate metal to metal contact. The wear bands are designed according to the side load requirements.

The primary compounds used for wear bands are filled PTFE, woven fabric reinforced polyester resin and bronze.

Visit our Product page and learn more about Hydraulic Cylinder Seals and

Hydraulic Cylinders, Mechanical Power offers.

Resourceful and innovative Marketing Pro, with 20+ years of progressive experience in the marketing and creative technology industry. Responsible for digital and traditional marketing efforts that promotes brand awareness, increases engagement, and drives revenue.