Here’s what we’ll cover:

Why Bearings Matter in Harsh Environments

How Vibration Affects Bearings

Bearing Types That Perform Under Pressure

Design and Material Choices

Keeping Bearings Alive With Proper Lubrication

Monitoring and Predictive Maintenance

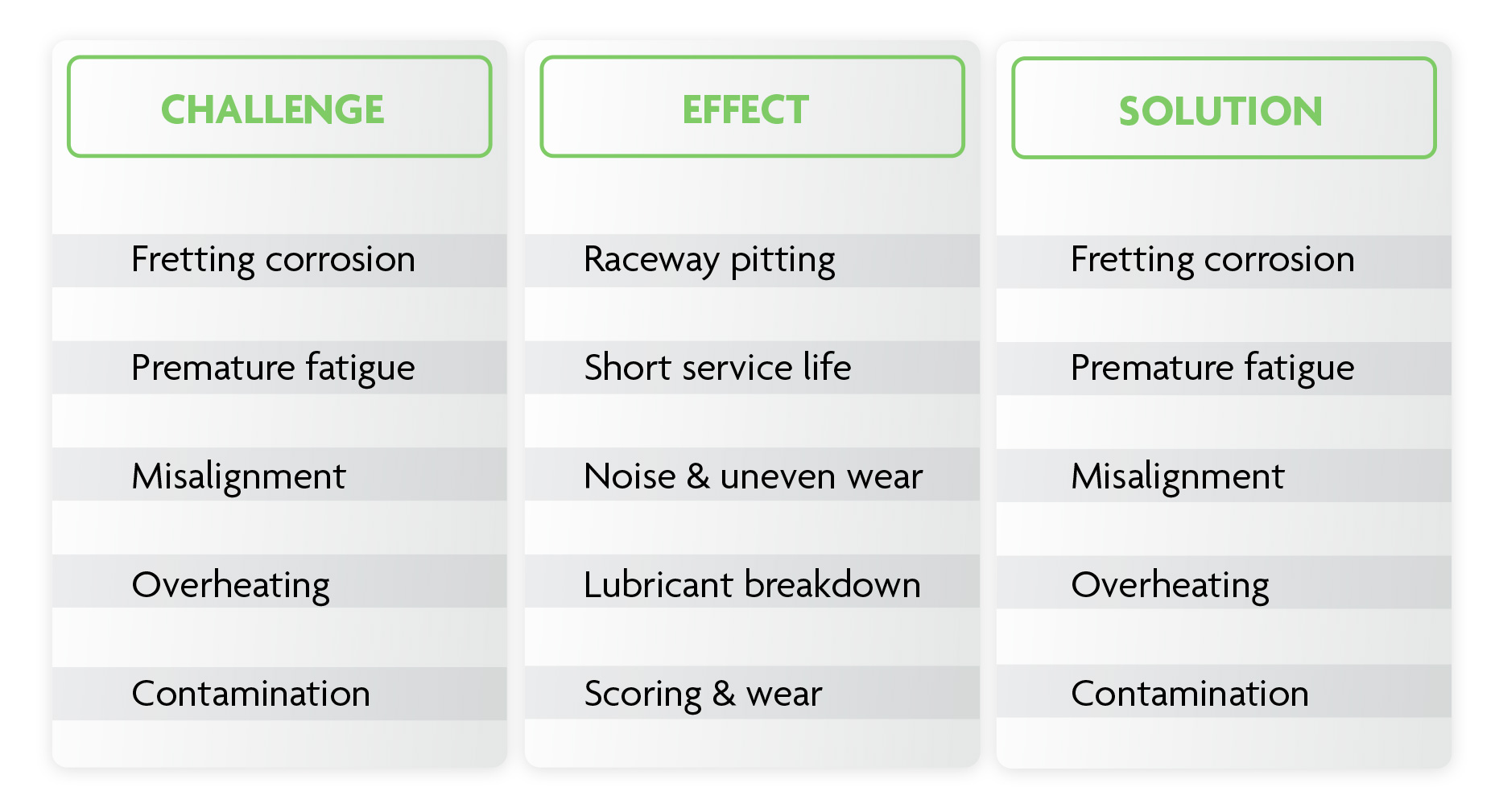

Challenges and Fixes

Frequently Asked Questions

Bottom Line

Key Takeaways

Bearings in high-vibration machinery need durability, precision fits, and advanced lubrication systems. The best options include spherical roller bearings, cylindrical roller bearings and hybrid ceramic bearings. Combined with vibration-damping housings and condition monitoring, these solutions extend equipment life and help avoid costly failures.

Why Bearings Matter in Harsh Environments

High-vibration environments — think rock crushers, compressors, pumps and heavy construction equipment — punish bearings more than standard applications. Constant shock loads, misalignment and heat degrade bearings quickly, and failures can stop production in its tracks. The right bearing selection can make the difference between routine uptime and repeated downtime.

Bearing Types That Perform Under Pressure

Spherical roller bearings

Self-aligning, highly durable, and built for heavy radial loads. The go-to choice for vibrating screens, crushers and conveyors.

Cylindrical roller bearings

Capable of handling large radial loads with reduced sliding friction. Common in motors and gearboxes under vibration.

Hybrid ceramic bearings

Steel races with ceramic rolling elements. Resist electrical pitting and reduce vibration transfer, common in aerospace and high-speed machinery.

Tapered roller bearings

Support combined radial and axial loads, well-suited for gear-driven equipment with vibration.

Did You Know?

For more than forty years Mechanical Power has been supplying high-quality bearings at competitive prices from around the world.

Maximize efficiency of your equipment.

How Vibration Affects Bearings

Microslip and fretting corrosion at roller contact points

Increased friction and heat that break down lubricants

Fatigue cracks in rolling elements

Misalignment that shortens service life

Design and Material Choices

Bearing life depends on a combination of carefully engineered details. Precision tolerances play a critical role in preventing micro-movement that could otherwise cause premature wear. The use of hardened steel alloys helps resist fatigue and extend durability, while brass or polyamide cages are designed to reduce resonance and noise during operation.

Modern sealing systems provide effective protection against contaminants, ensuring a cleaner operating environment. In addition, advanced lubrication channels keep oil or grease properly in place, even under demanding conditions and shock loads, allowing the bearing to perform reliably over time.

Challenges and Fixes

Keeping Bearings Alive With Proper Lubrication

Use greases with extreme pressure (EP) additives or high-viscosity oils.

Automatic lubricators help maintain a steady film.

Solid lubricants are an option for the harshest conditions.

Oil analysis can reveal wear particles early, before a bearing gives out.

Monitoring and Predictive Maintenance

Vibration analysis detects inner race damage before it becomes audible.

Acoustic monitoring identifies micro-cracks.

Infrared thermography spots overheating from lubrication failure.

IoT sensors allow continuous, real-time tracking of bearing performance.

How Can MPI Help You?

We can supply all of your bearing needs.

Click the RFQ button, email us at [email protected]

or call us at 847.487.0070 for more information.

Tell us what you need and we will save you time and money.

Bottom Line

Bearings in high-vibration machinery demand more than a one-size-fits-all approach. Choosing the right bearing, applying the right lubrication and keeping a close eye on performance are essential to reducing downtime and protecting expensive assets.